Packing

Quality Check

The packaging process begins with a thorough inspection of each product. We carefully examine every piece to catch and correct any potential issues that may have been overlooked during production.

Pre-Pack Assembly

Before packaging, we fully assemble your product. This allows us to identify and resolve any possible issues in advance, ensuring you’ll have a smooth, hassle-free setup experience at home.

Wrapping

After assembly, we disassemble the product and move on to the wrapping stage. Identical parts are wrapped together in protective bags to shield them from moisture and prevent damage during transit.

Numbering

Each wrapped part is labeled according to the numbers on the assembly guide. This makes it easy for you to follow the instructions and complete the setup without confusion.

Inner Boxing

The wrapped and labeled parts are then neatly placed into an inner box—referred to as the "tray"—to keep everything organized before being packed into the outer box.

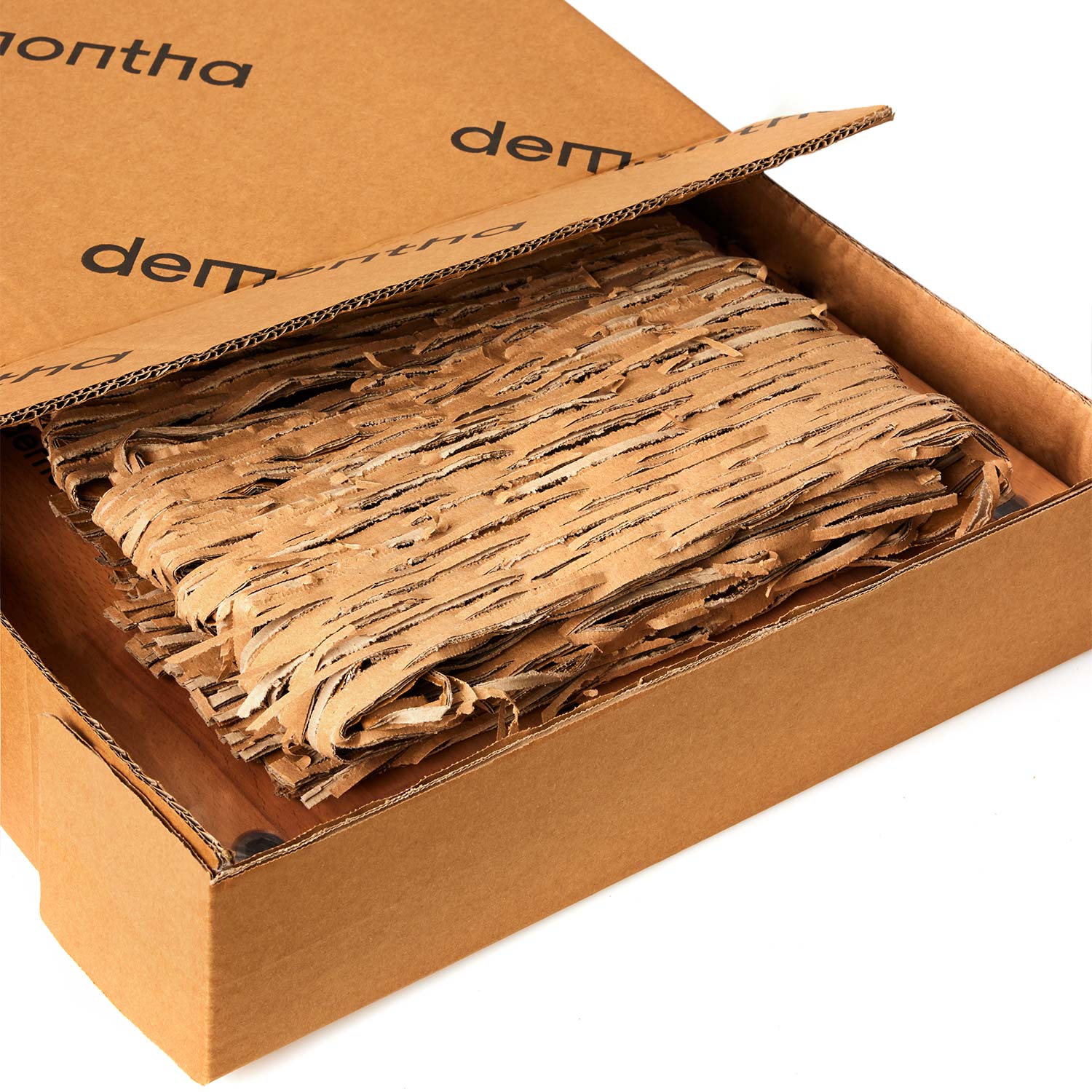

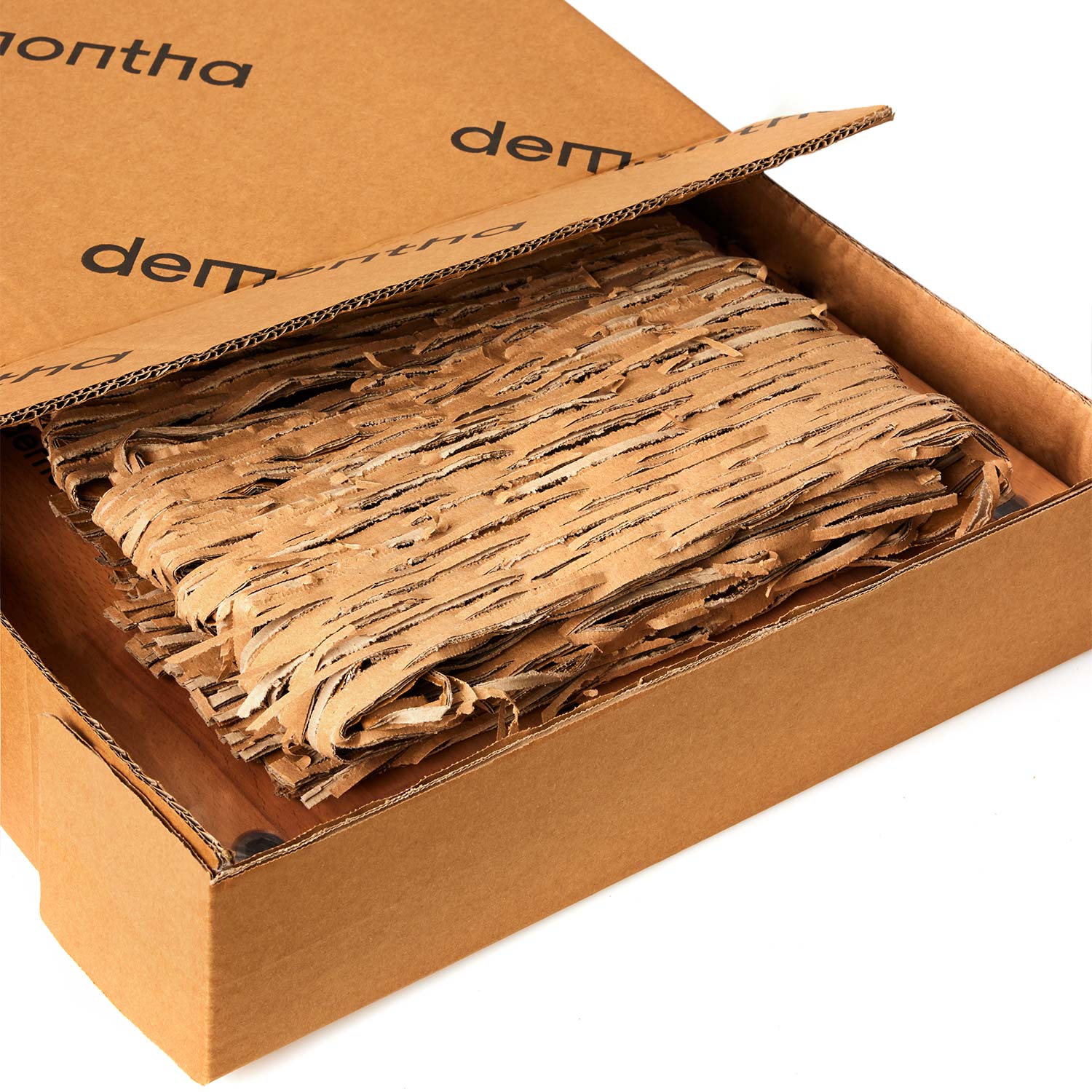

Padding

We fill any empty spaces in the inner box with recycled cardboard for cushioning. This reduces the impact of vibrations and shocks that may occur during shipping.

Outer Boxing

The final step is outer boxing. We place the inner box into a durable, high-grammage kraft cardboard outer box, secure it with strapping, and prepare it for a safe journey to your doorstep.